Keep metal parts clean and corrosion-free with RST Foam for Rust Prevention—a lightweight, flexible, customizable, easy solution for protecting your metal equipment and parts.

If you’re a manufacturer, you know how important it is to protect your product, and rust can cause costly damage, resulting in production slowdowns and shutdowns. Traditional rust prevention methods like messy and hazardous RP oils and grease, or even some VCI paper or poly applications, can be labor intensive. Every metal part must be individually handled to ensure they are protected, which is a drain on your company’s resources.

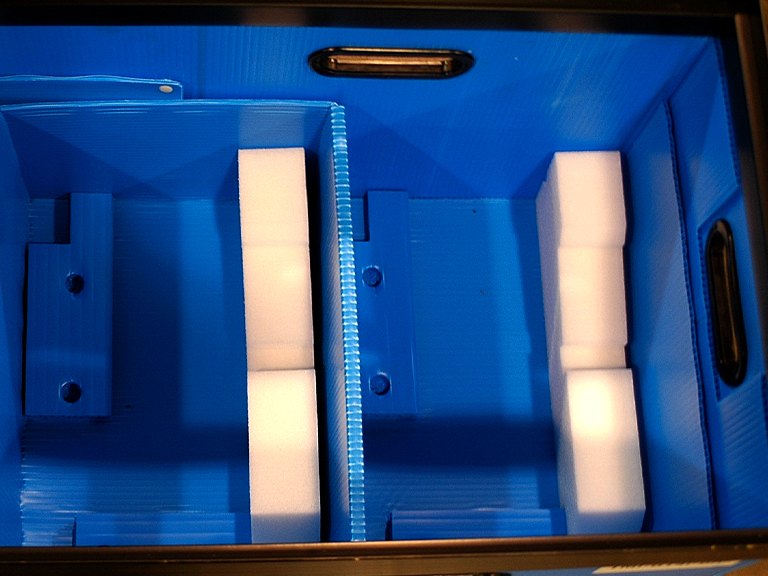

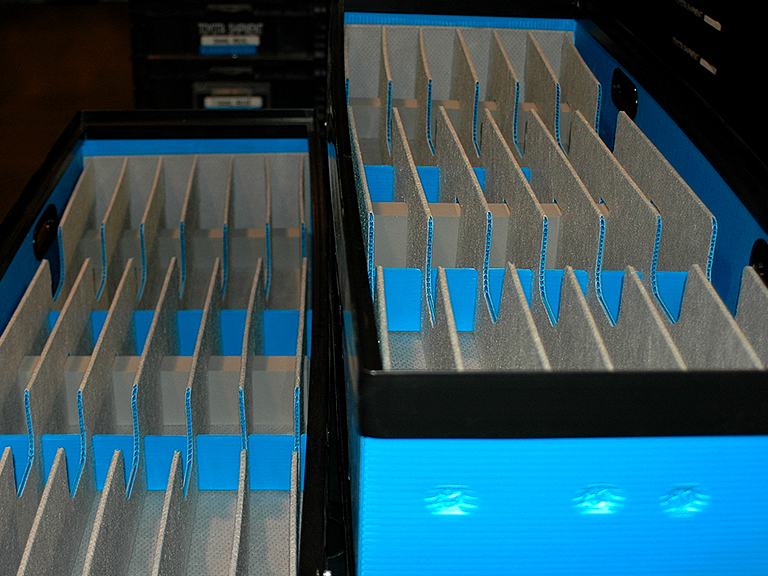

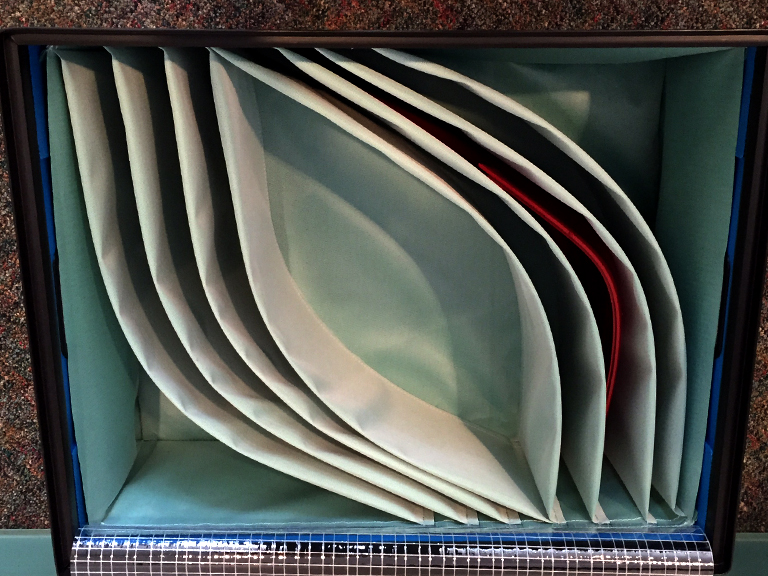

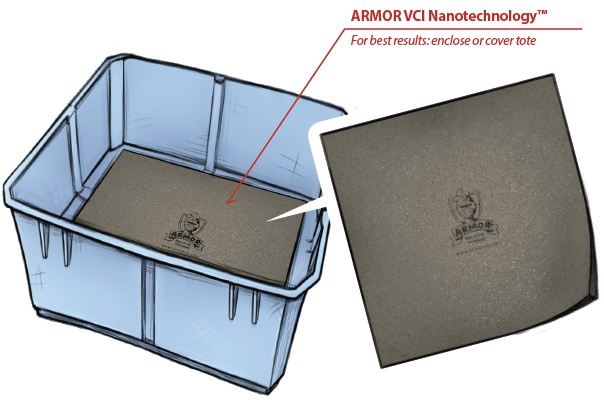

By working with our partners, the Eradicators of Rust at Armor Protective Packaging®, Diverse Global has developed RST Foam for Rust Prevention—a quick and easy solution that can save you time and money. This new foam is specifically designed for use in your material handling container when you are shipping or storing metal parts.

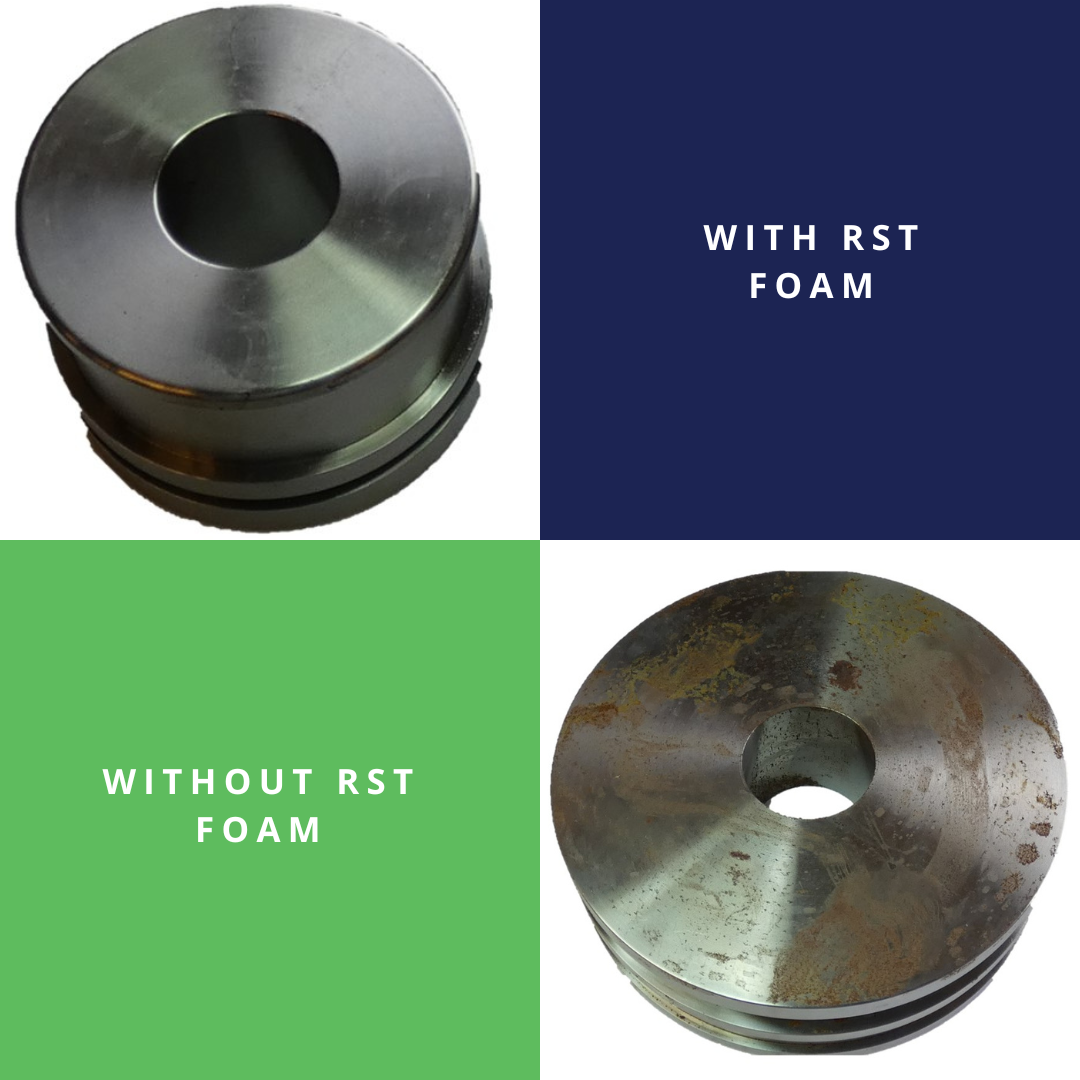

We’ve added ARMOR’s special formula of rust-preventing VCI (vapor corrosion inhibitor) to the foam. In the presence of metal, the VCI releases vapors that attach to the surface of the metal to create a blanket of protection that blocks moisture and other corrosive elements. With RST Foam for Rust Prevention, your metal parts will stay clean and rust-free, reducing the need for frequent maintenance and replacements.

Our RST Foam for Rust Prevention underwent rigorous testing to confirm its effectiveness. When subjected to a controlled environment with a relative humidity of 95-99%, our RST Foam demonstrated a 100% success rate in preventing rust and corrosion of metal parts.

Download our case study to see how our RST Foam for Rust Prevention with VCI nanotechnology can save your metal parts.